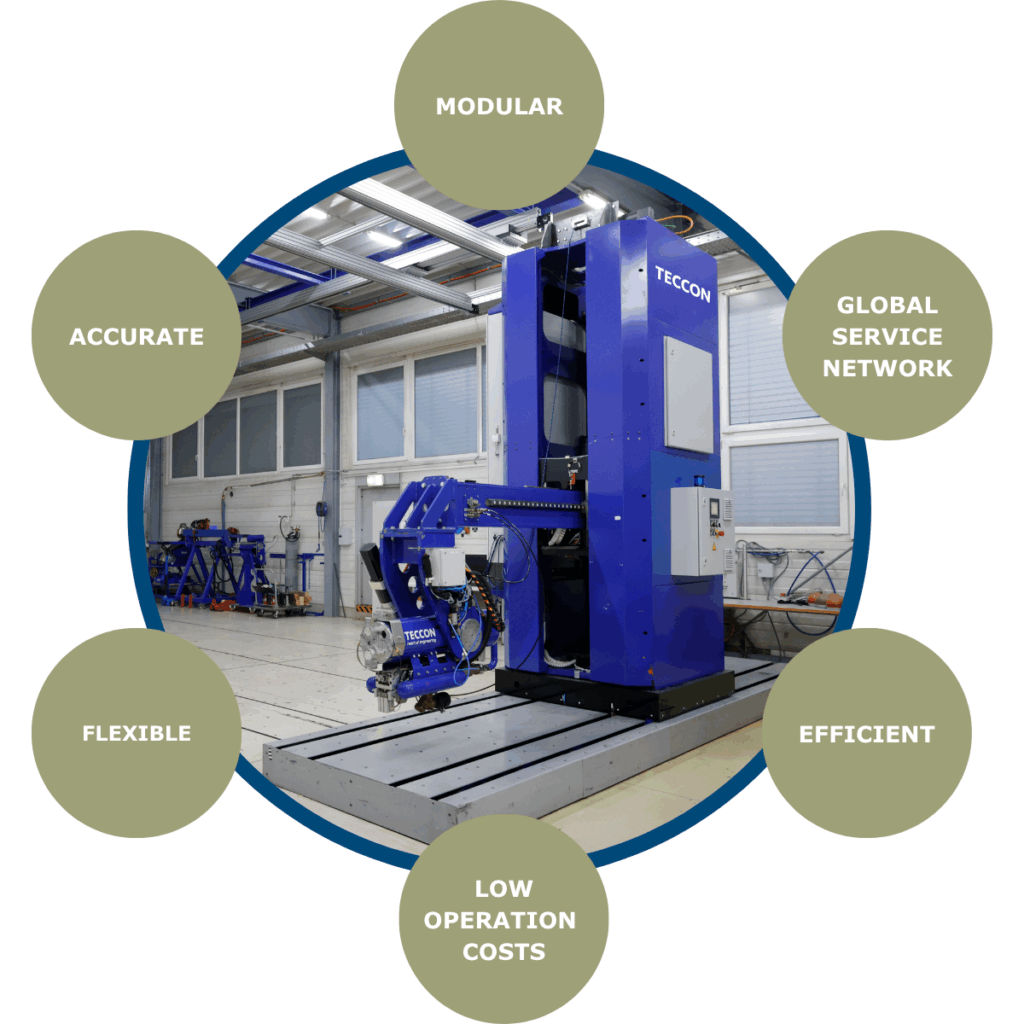

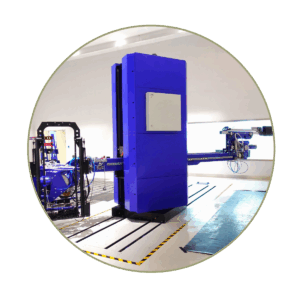

Our modular universal impactor test system

Our innovative testing system provides you with a flexible and future-proof system that is tailored to your individual requirements.

- Modular system: A basic tower unit that can be extended as required.

- Simple customization: Three different launchers are available – replacement is quick and easy.

- Variety of tests: Over 20 standardised load cases are already integrated.

- Central user interface: All load cases are controlled via a single, intuitive interface.

- Individual expandability: In addition to the standard setups, customized test configurations can be added at any time.

Our universal testing system enables precise, reproducible and flexible impact tests – from standardized procedures to customer-specific special solutions. It covers a wide range of component tests and load cases in accordance with the latest legal requirements and combines maximum precision, efficiency and flexibility in a single system.

System performance

- Speed accuracy: ± 0.1 – 0.2 km/h (depending on load case)

- Accuracy of the speed measurement: ± 0.0036 km/h

- Head impact tests: 6 – 10 tests/day

- Leg form tests: 3 – 6 tests/day

- Upper leg form tests: 3 – 6 tests/day

- Productivity (with 1 operator + 1 assistant per shift)

- Y-direction: 4,000 mm

- Z-direction: 2,200 mm Travel paths of the system (customizable)

- X-direction: 2,100 mm

- Rotation: 360°

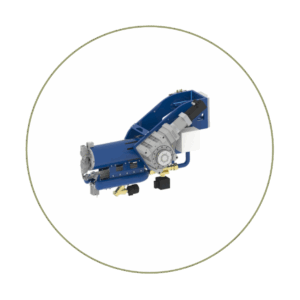

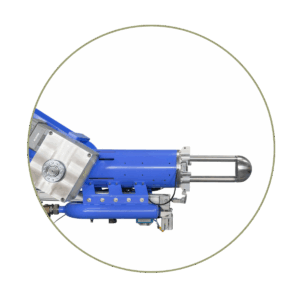

Launcher technology

TECCON has developed the Advanced Speed Control (ASC) – a closed-loop speed control system – to ensure minimal speed deviations and maximum reproducibility. All ASC launchers are driven by nitrogen and additionally equipped with an electric linear motor for precise speed control.

![]()

A key advantage of the ASC system is that no pre-tests are required to verify the impact speed. Even after long downtimes, ASC enables “first shot right” testing.

Advantages of the TECCON ASC launcher:

- Smallest and most flexible launcher in the world (Launcher XS)

- Maximum accuracy thanks to closed high-speed control loop

- No pre-test required for speed adjustment & low operating costs (approx. 1 $/test)

- No hydraulic system – therefore minimal maintenance costs and reduced downtimes

- Quickly switch between different launchers on the base system

Impactor tests

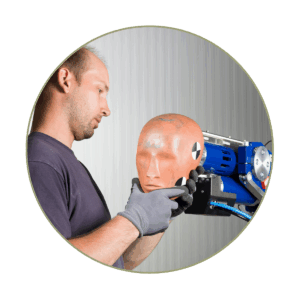

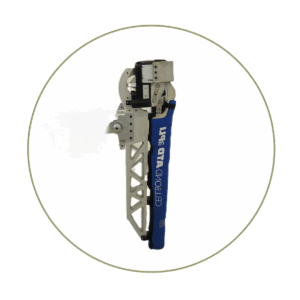

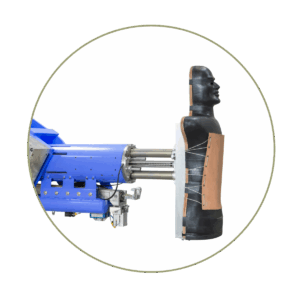

Launcher XS

Launcher M

Launcher L

Our test equipment at a glance

Launcher XS for FMVSS 201u tests

The Launcher XS was specially developed for testing in accordance with FMVSS 201u.

Technical specifications Launcher XS:

- Maximum impact energy: 120 J

- Angle range: –10° to +50°

- Angle adjustment: mechanical

FMH specification:

- Test speed: 19.3 and 24.1 km/h

- Impact mass: 4.5 kg

- Impact type: free flying

- Impact accuracy: ± 5 mm around the target

- Speed accuracy: ± 0.2 km/h with ASC

- Drive technology: Hybrid N₂ + linear motor

Special features: Also available as a retrofit solution for existing systems or robots.

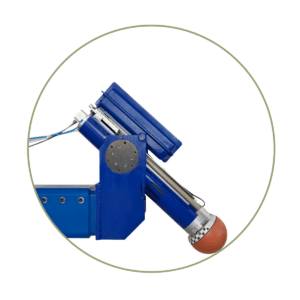

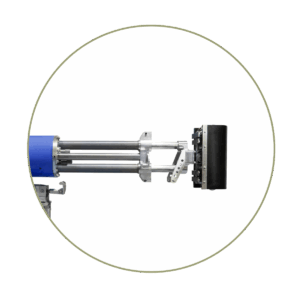

Launcher M with ASC – for pedestrian protection and special tests

The Launcher M is used for pedestrian protection head impact tests as well as for EMI and SAE pendulum tests.

Technical specifications Launcher M:

- Maximum impact energy: 340 J

- Angle adjustment: mechanical

- Drop weight: 3.5 and 4.5 kg

- Speed range: 25–42 km/h

- Test speed: 35 und 40 km/h

- Test speed: 35 and 40 km/h

- Repeatability: ± 0.2 km/h with ASC (1st test is correct immediately)

- Impact accuracy: ± 5 mm radius around the target

- Impact angle: –25° to –90°

- Angular accuracy: ± 1°

- Trajectory: free flight | guided

- Drive technology: Hybrid N₂ + linear motor

UN R127.04, all NCAPs etc.

FMVSS 226

ECE-R21 and similar

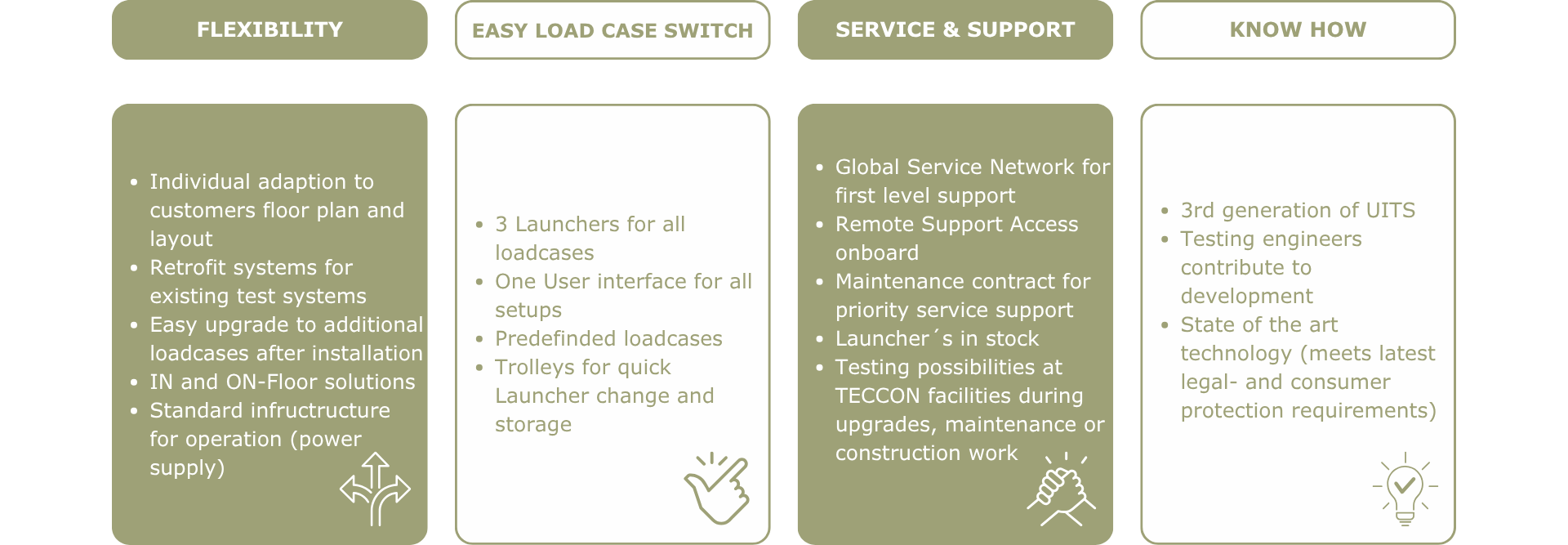

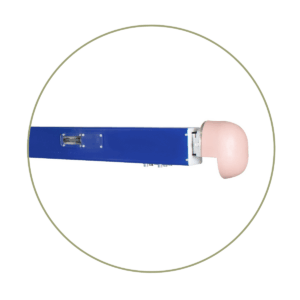

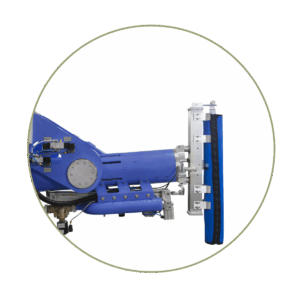

Launcher L with ASC – for pedestrian protection leg impact tests and more

The Launcher L is used for pedestrian protection leg impact tests (TRL Leg, FlexPLI, aPLI, Upper Leg), misuse tests (PDI-2, Small Animal, etc.), linearly guided impact tests and body block impact tests.

Technical data Launcher L

- Maximum impact energy: 3000 J

- Acceleration distance: 460 mm

- Free flight path: 1000 mm (with free flight)

- Speed range: 20–55 km/h (depending on weight)

- Speed accuracy: up to ± 0.2 km/h with ASC

- Repeatability: up to ± 0.2 km/h with ASC

- Impact accuracy: ± 5 mm

- Impact angle: –90° to +15°

- Angular accuracy: ± 2°

- Angle adjustment: electric

- Drive technology: Hybrid N₂ + Linearmotor

- Weight: 370 kg

Special features

- Highest precision for demanding pedestrian protection tests

- Flexibly adjustable angles and speeds

- Robust construction for long-term performance

Pedestrian protection FlexPLI:

UN R127.04

GTR 9

KMVSS 102-2

all NCAPs

Pedestrian protection aPLI:

Euro NCAP

JNCAP

KNCAP

C-NCAP

Pedestrian protection Upper leg:

UN R127.04

GTR 9

KMVSS 102-2

all NCAPs

Impactor:

ECE-R12

FMVSS 203

GB 11557

Body Block Impactor:

ECE-R12

ECE-R95

FMVSS 203

GB 11557

PDI-2:

Misuse impactors, speed up to 55 km/h, TECCON temperature chamber tests:

-30 °C to +90 °C

Tests for pedestrian protection– Active Bonnet

Our module for active bonnet testing offers precise and realistic testing options for a wide range of load cases in the field of pedestrian protection. It covers a broad spectrum of scenarios to ensure the safety and functionality of modern vehicles.

Covered load cases:

- PDI-2 (Pedestrian Detection Impact)

- Stone (stone impact)

- Bird (bird strike)

- Branch (branch impact)

- Small Animal

- Basketball

- Soccer Ball

- Trash Bin

Advantages of the module:

- High reproducibility of tests

- Precise simulation of real-life collision scenarios

- Adaptable to different vehicle models

- Supports compliance with legal requirements

Our Active Bonnet Module ensures maximum test accuracy and increases pedestrian safety through innovative test solutions.

Customized Modules – Customised to your requirements

Customization – our daily business

We develop and manufacture all testing equipment in-house and tailor it specifically to our customers’ requirements. Whether dimensions, speeds, traverse paths or special load cases outside standardised test protocols – we implement tailor-made solutions.

Examples of our customisation options:

- Length, width and traverse paths according to customer specifications

- Adjustment of speed ranges

- Development of special load cases

- Integration of additional functions and interfaces

With our custom modules, you benefit from flexibility, precision and a solution that is perfectly tailored to your testing requirements.

MINI Tower

Tower with rotation

2 Towers on 1 machine bed

Why TECCON Austria?

Our customers benefit from the highest quality, customized flexibility and fast support. With transparent pricing, a global service network and local availability of spare parts, we stand for reliability and continuity. Development and production in Austria also guarantee precision and sustainability – reasons that speak for TECCON Austria.

QUALITY

Production, pre-installation and quality control in Austria

FLEXIBILITY

Customer-specific adaptation of test benches and load cases

SPEED

Short response times for support, maintenance and calibration

TRANSPARENCY

No hidden costs – fixed price

GLOBAL NETWORK

Support guaranteed by global service network

MADE IN AUSTRIA

Development and production at the headquarters in Austria

CONTINUITY

Local availability of spare parts, maintenance contracts and calibration

Your personal contact

We offer you a single point of contact for all requirements relating to test benches in the field of passive safety. Rely on our expertise for customized test benches that guarantee maximum safety and precision.

Get in touch with us today!

Friedrich JANDL

E-mail: sales@teccon-austria.com

Telephone number: +43 (0) 3124 203 0

Get in touch with us today!

With our services and expertise, we offer you a reliable partner for any testing requirements in the field of passive safety. From the testing and validation of safety components to crash tests – we support you in all phases of your projects. Rely on our expertise for tailor-made test solutions that ensure maximum safety and innovation.

Quality certificates & partnerships

Our high quality standards and the continuous development of our processes are reflected in our certifications. As an officially accredited test laboratory, we meet the strict requirements of Euro NCAP to comprehensively test the safety of vehicles. Our ISO 17025 certification guarantees the competence of our test laboratories and the reliability of our test results. The ISO 9001:2015 quality management system confirms our structured approach and commitment to continuous improvement. With TISAX certification, we meet the highest standards for information security and the protection of sensitive data in the automotive industry. With our Passive Safety Center, we are a partner laboratory of ALEE – Alliance des laboratoires d’essai européenne GmbH and part of a strong network for vehicle safety in Europe

Partnerships & Accreditations

Certificates