Engineering & Complexity Management

Our engineering experts guide you through the entire development process – from the early concept phase through to series production.

We ensure that all legal requirements and customer-relevant passive safety requirements are reliably met. Using state-of-the-art simulation methods and innovative tools, we shorten development times and increase the quality of the results at the same time. In this way, we support you in bringing efficient and safe vehicles onto the market.

Our services

Total vehicle protection

Occupant protection

Restraint system development

Interior development

Exterior development

Material characterization

Our test areas

Total vehicle protection

✔ Front, rear and side crash simulations, tests & validation

✔ Integrity of the fuel system (simulation & test)

✔ Low-speed crash scenarios (AZT, bumpers, …)

✔ Structural tests, simulation & validation

✔ Development of battery protection structures

✔ Structural optimization & modal analysis

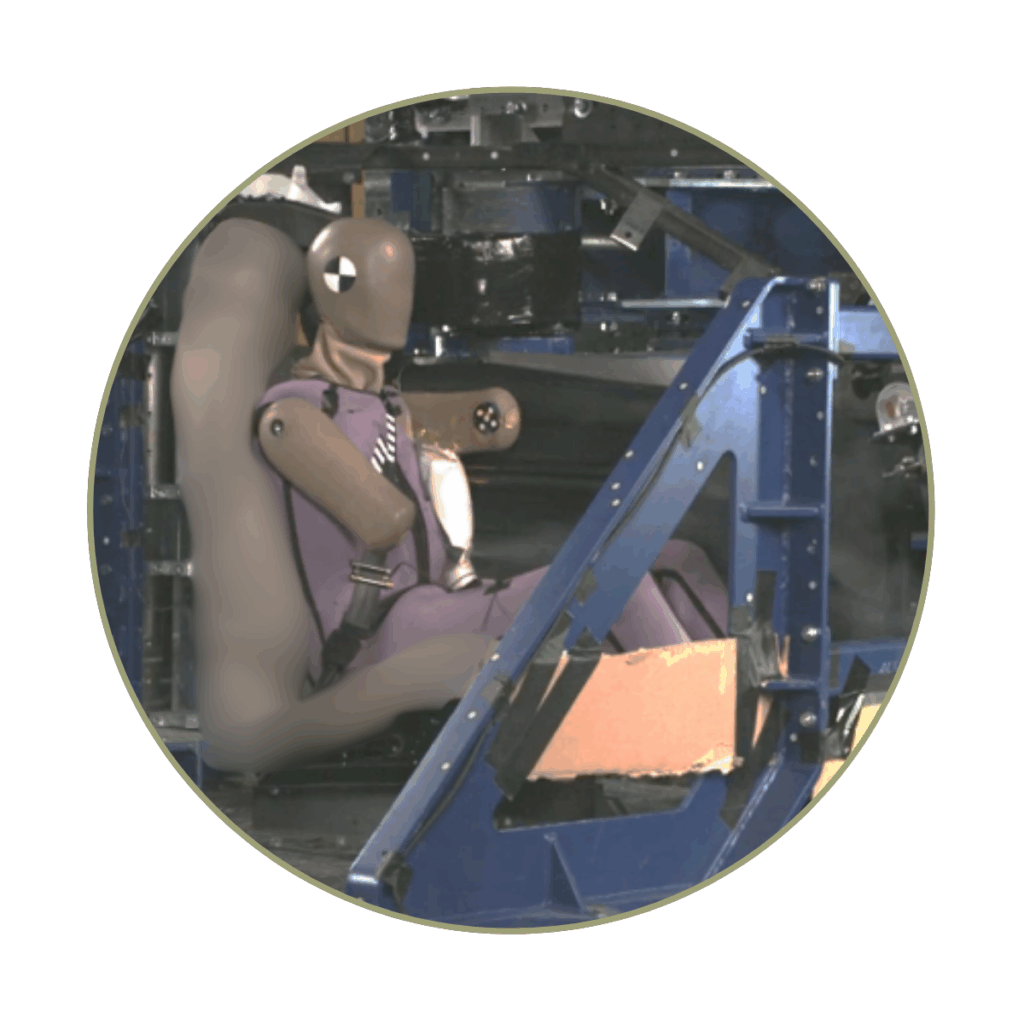

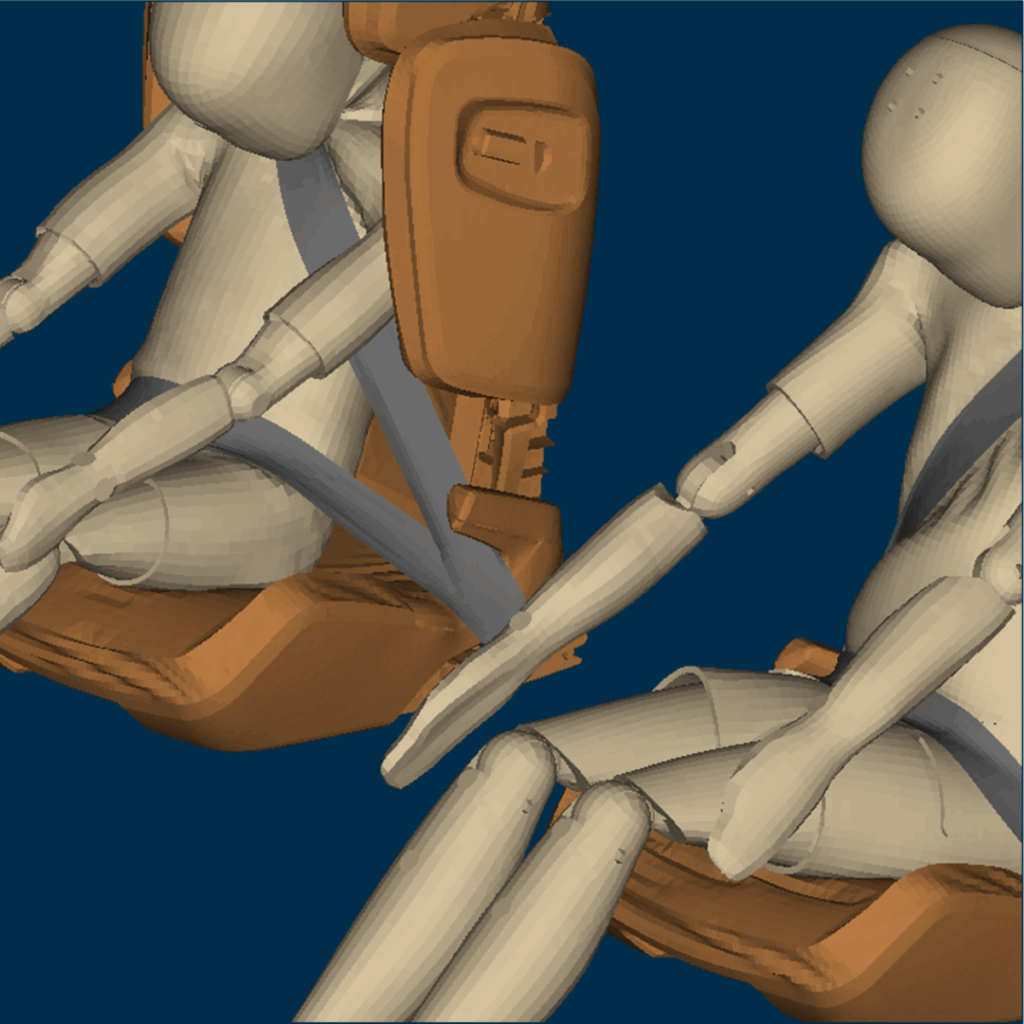

Occupant protection system development

Integration and optimization of restraint systems in accordance with global regulations

✔ Side slide systems for restraint system integration

✔ Extensive experience in child safety requirements

✔ Dashboard rating (ECE-R21 and FMVSS201L)

✔ Optimization of instrument panel (IP panel) and joints (split lines)

Virtual restraint system development

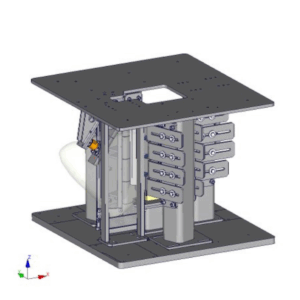

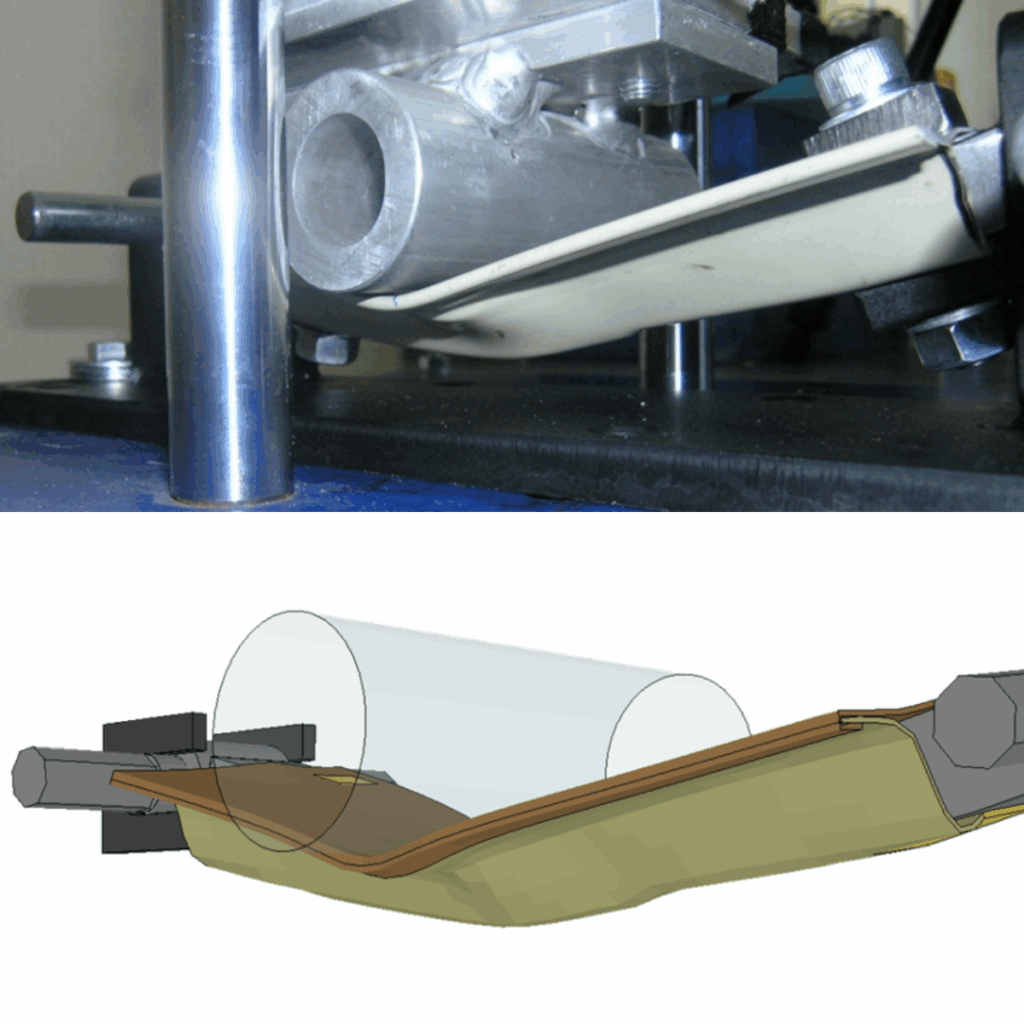

Seat Assessment Machine (SAM)

- Load case-related dynamic tests for correlation of hardware and

CAE seat model - Lateral and frontal crash load cases

- Analysis of the seat’s restraint effect

- Higher validation quality of the seat models

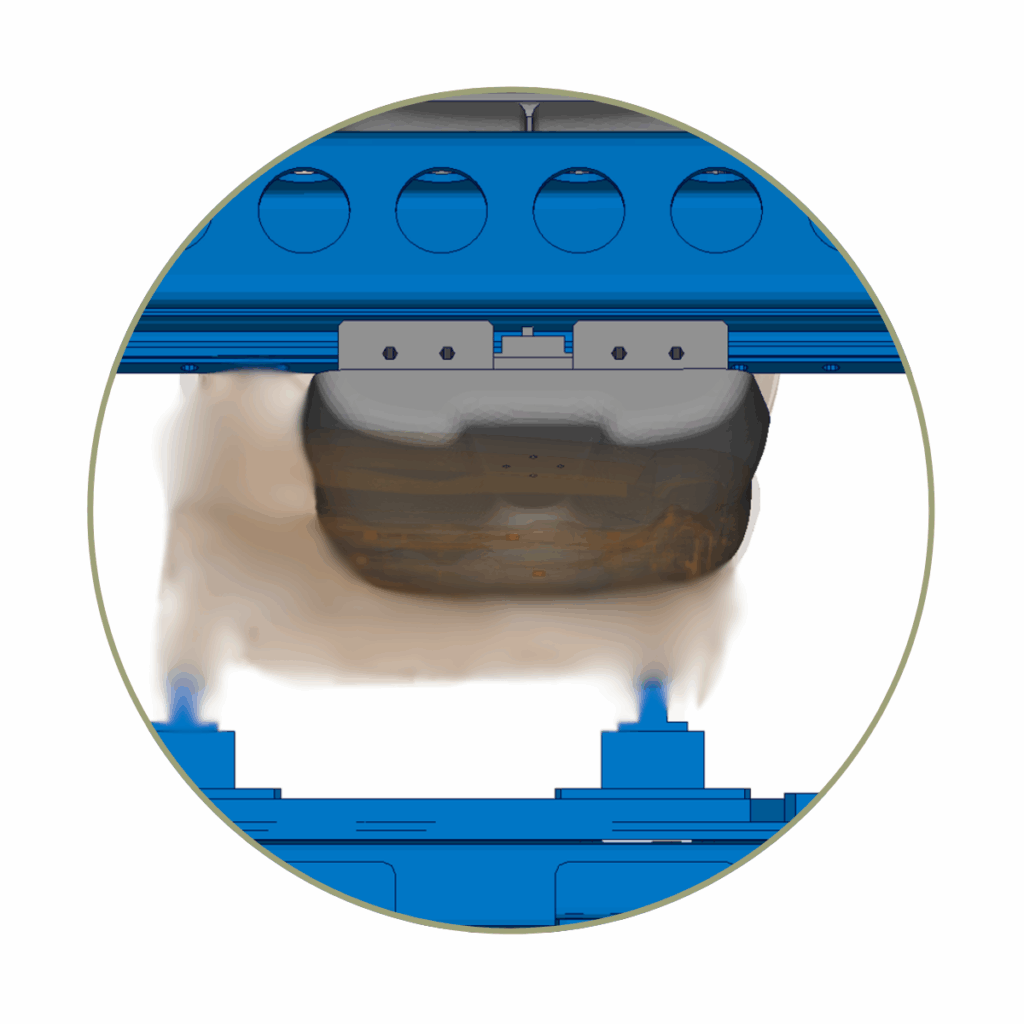

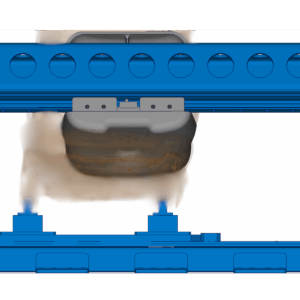

Airbag Research & Validation Infrastructure (ARVIN)

- Verification and validation of the thorax airbag

- Development of measures (e.g. OOP – Out of Position)

- Measurement of forces in the airbag environment

- Clarification of validation issues in the system

- Reduction of disruptive influencing factors

Interior development

FMVSS 201u

We assume full development responsibility for FMVSS 201u and accompany the entire process from the concept phase to series production.

Design & concept support: Expert assessments, feasibility and risk analyses

![]()

Simulation & virtual development: Virtual development processes and model validation

System engineering & tests: Holistic process understanding, prototype & certification tests

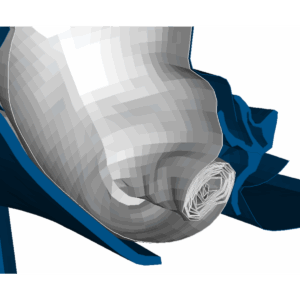

Virtual curtain airbag integration

We support the integration of curtain airbags from the early design phase through to series production – completely virtually and efficiently.

- Simulation of the deployment behavior of the curtain airbag

- Optimization of interaction with interior components at various temperatures (-40 °C to +90 °C)

- Analysis of factors influencing the unfolding behavior (temperature, folding variants)

- Temperature-dependent failure forecasts

- Development of measures in close coordination with other disciplines (e.g. FMVSS 201u, FMVSS 214)

Exterior development

Pedestrian protection

We assume full development responsibility for pedestrian protection systems – from the early concept phase through to series production.

Simulation & virtual development: Virtual development processes and validation of FE models

System engineering & testing: Process understanding, prototype & conformity tests, accredited testing services

Integration & development: Consideration of pedestrian protection, bumper requirements and sensor integration

PedPro Sensor – Simulation and validation

We support the complete virtual development of PedPro systems for active hoods.

- Simulation and optimization of sensor signals over the entire temperature range: LT, RT, HT

- Simultaneous PedPro development for optimum system integration

- Virtual support for signal discrimination – “No-Fire” / “Must-Fire”

- Simulation of pressure sensor signals for left and right side

- Verification of pedestrian protection criteria: HTD Pedestrian, HIT, Upper-Body-Influence

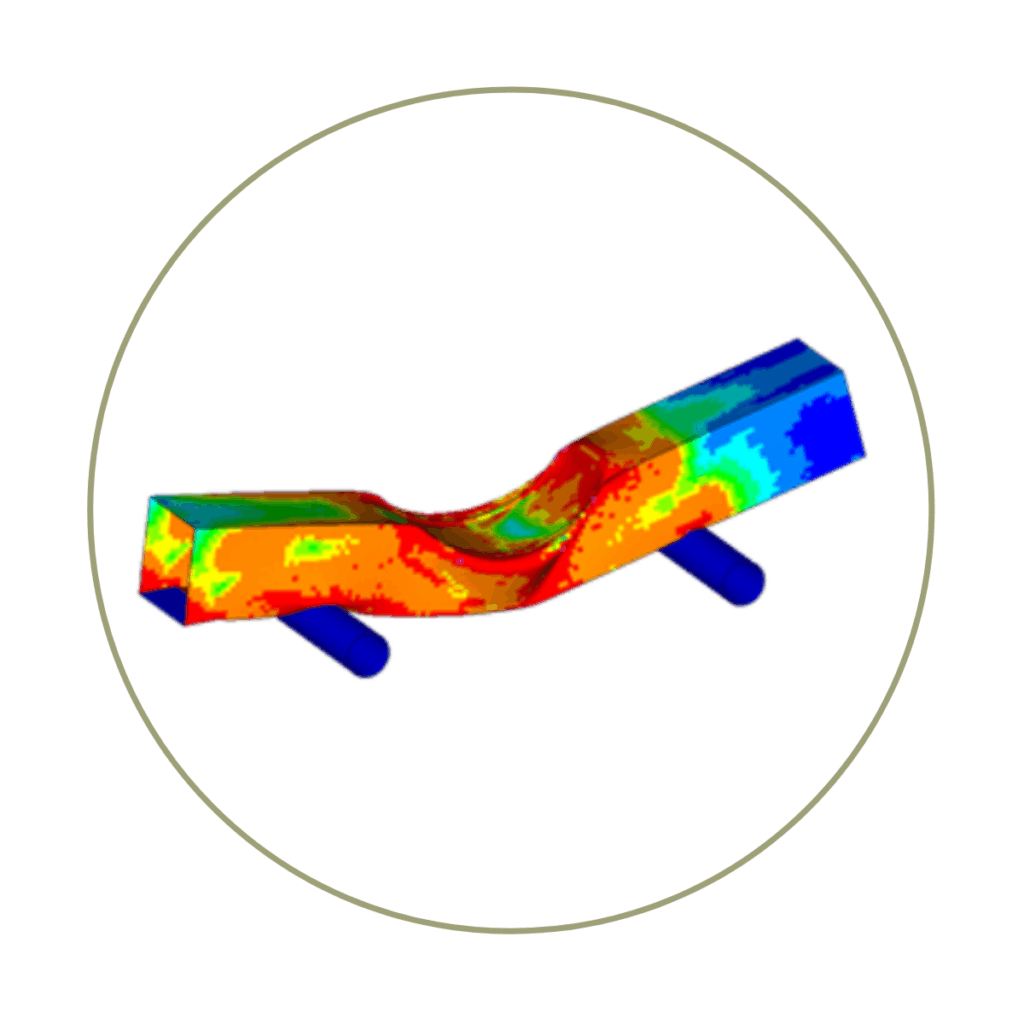

Material characterization

Scope 1: Creation of validated material cards

- Plastics, metals, foams, composites

- Basis for precise simulations and system model

Scope 2: Validation of components / subsystems

- Examination of more complex components separately

- Validated components can be integrated directly into complete systems

- Examples: Vehicle frame, connecting elements, headlights

Scope 3: Validation of the complete system

- Review and validation of the entire simulation model

- Examples: Overall vehicle model, pedestrian protection model

Why TECCON Austria?

Test and development center since 1998

High flexibility

Remote testing

Virtual sharing via HoloLens, data transfer via file cloud

Strong global partnerships

Remote Testing at TECCON Austria

TECCON Austria now makes passive safety testing more flexible and efficient than ever before!

On-site test release means a lot of time and travel costs for our customers. But now there is an innovative solution: remote testing.

With Microsoft HoloLens and Microsoft Teams, you can be there live – without having to travel. A TECCON Austria employee can guide you through the test preparations by wearing the HoloLens, and you can discuss all the details directly with our test staff. Once all points have been clarified, you can conveniently approve the test remotely.

This saves time and money and makes the test even more efficient.

Your personal contact

We offer you simulations, validations and optimization in the field of passive safety. Take advantage of our expertise to develop solutions for your requirements that focus on both safety and innovation.

Get in touch with us today!

Sebastian DORNBUSCH

E-mail: sales@teccon-austria.com

Telephone number: +43 (0) 3124 203 0

Get in touch with us today!

With our services and expertise, we offer you a reliable partner for any testing requirements in the field of passive safety. From the testing and validation of safety components to crash tests – we support you in all phases of your projects. Rely on our expertise for tailor-made test solutions that ensure maximum safety and innovation.

Quality certificates & partnerships

Our high quality standards and the continuous development of our processes are reflected in our certifications. As an officially accredited test laboratory, we meet the strict requirements of Euro NCAP to comprehensively test the safety of vehicles. Our ISO 17025 certification guarantees the competence of our test laboratories and the reliability of our test results. The ISO 9001:2015 quality management system confirms our structured approach and commitment to continuous improvement. With TISAX certification, we meet the highest standards for information security and the protection of sensitive data in the automotive industry. With our Passive Safety Center, we are a partner laboratory of ALEE – Alliance des laboratoires d’essai européenne GmbH and part of a strong network for vehicle safety in Europe

Partnerships & Accreditations

Certificates